Ultra-precision Live Centre, machine tool parts in machining. The unique processing technology ensures the accuracy and stability of the product and prolongs the service life of the product. It is suitable for all kinds of machine tools, such as milling machine, grinding machine, engraving machine, etc. it can be used in all kinds of high-precision and well balanced processing machines, such as boring, milling, drilling, reaming, tapping, engraving, etc.

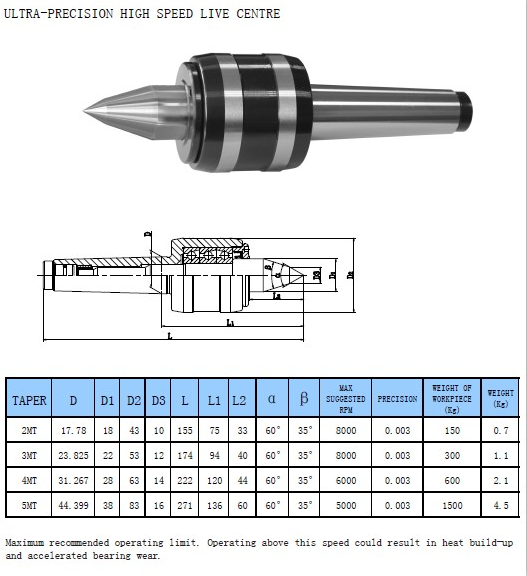

Morse Taper Live Centre Specifications

1. Ultra-precision High Speed Live Centre Center assembly bearings, thrust bearings

2. High Speed Live Centre Can be used at medium speed

3. Shaft made of alloy steel, through heat treatment

4.HRC58-60, handle super steel features and high durability.

5. The plunger uses precision-matched angular contact ball bearings and roller bearings to further improve the accuracy of the rotary tip. 6. Front with dust-proof, waterproof seal, to extend the life of the top

7. Suitable for precision machining CNC high speed heavy load.

8. Ultra-precision Live Centre Accuracy: 0.003mm

9. Speed Live Centre Material: Body: 40Cr HRC40-45

Sharp: GGr15 HRC58-62

Product advantages

1 High-precision waterproof and oil-resistant Morse lathe live top, the number of revolutions 3000. Precision 0.003 thrust bearing and needle roller bearings for high-speed CNC lathe machining in the load, the mandrel extended to the taper shank, to maximize cutting Performance, reduce the impact of vibration, the use of alloy steel mandrel, heat treatment after the hardness HRc60o ± 2o, with high rigidity and high wear resistance, dust-proof front seal to prevent cutting fluid and dust into the bearings.

2 Ultra-precision High Speed Live Center body material: 40Cr forgings, heat treatment hardness HRC40 ~ 42

3-axis tip material: alloy tool steel, heat treatment hardness HRC58-60, with high rigidity and wear resistance.

Precision cylindrical roller bearings choice

4-pin roller bearing bearings.